Leather cutting is an essential step in the creation of leather goods: bags, belts, cases, accessories, or garments. Choosing the right cutting tool makes all the difference between a professional finish and an uneven cut. In this guide, discover the best tools for cutting leather according to your needs, your type of leather, and your leathercraft or DIY projects.

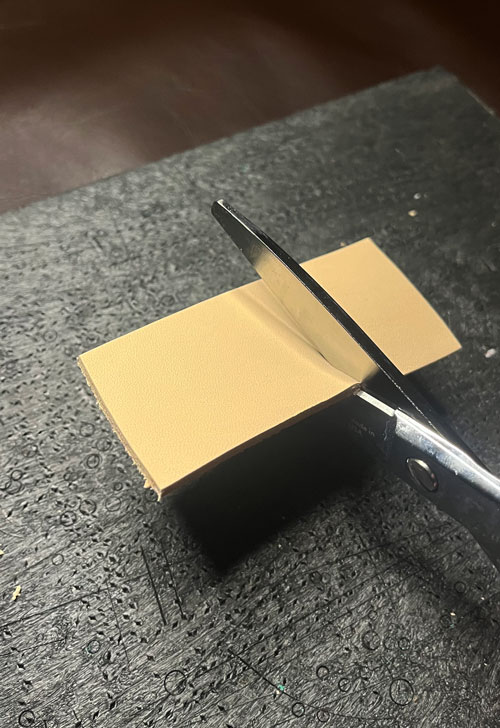

1. Leather scissors

Leather scissors are perfect for cutting soft leathers such as lambskin, upholstery leather, or relatively thin vegetable-tanned leathers. They come in different blade sizes:

- Short blade: ideal for precise cuts and rounded shapes.

- Long blade: efficient for straight cuts on large leather surfaces.

2. Retractable utility knife

A must-have in any leather workshop, the utility knife allows you to make straight, curved, or complex cuts. It works with many types of leather, whether soft or firmer.

Advantages:

- Retractable or fixed blade depending on use

- Quick and easy blade replacement

- No sharpening required

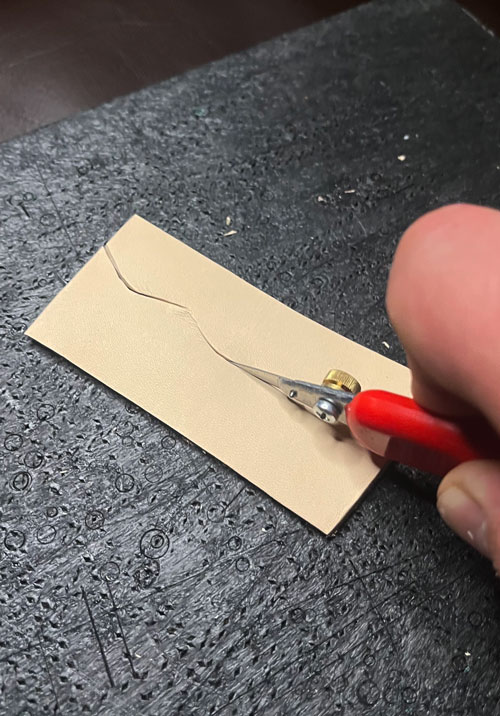

3. Precision knife (leathercraft scalpel)

Perfect for fine and detailed cuts, the precision knife is used for inlays, filigree, or cutting complex patterns. It allows access to tight areas where other tools cannot reach.

Perfect for: leather marquetry, artistic creations, lettering, or cut-out logos.

4. Rotary cutter

The rotary cutter is the tool of choice for quickly cutting soft leathers such as deerskin, lambskin, or suede. It cuts without distorting the material and is very useful for long straight cuts, even on firm leather.

Uses:

- Clean straight cuts

- Creating even fringes

- Quick cutting of large surfaces

5. Round knife

An iconic tool of leatherworkers, the round knife is versatile: it is used to cut, skive, and bevel leather, even thick hides. Used freehand or with a template, it is a must-have in professional leathercraft.

Note: its edge must be regularly maintained (sharpening and polishing) to keep a razor-sharp cut.

Tip: use a hard surface (marble or glass) when skiving to preserve the blade.

6. Straight skiving knife

Traditional and efficient, the straight skiving knife is ideal for thinning the edges of vegetable-tanned leather or making clean, precise cuts. It offers excellent control for high-end finishes.

Recommended for: advanced leathercraft enthusiasts and professional-quality finishing.

7. Strap cutter

The strap cutter is essential for creating even leather strips, perfect for belts, bag handles, straps, or bridles.

Benefits:

- Easy width adjustment

- Perfectly straight strap cutting

- Suitable for rigid or semi-soft leathers

Tip: best used with medium to thick vegetable-tanned leather.

8. Lace cutter

Designed to turn a leather scrap into a continuous lace, the lace cutter is ideal for braiding, decoration, saddle stitching, or bag lacing.

Function: it allows you to cut a regular spiral from a round or square piece of soft leather.

Tip: a perfect tool to recycle your leather scraps and get meters of laces at low cost.

Summary table: which tool for which use?

| Leather type / project | Recommended tool | Why? |

|---|---|---|

| Soft / thin leather | Rotary cutter, scissors | Clean cut without distortion |

| Thick / rigid leather | Utility knife, round knife | Precision and power |

| Details and small patterns | Precision knife, scalpel | Fine work and tight areas |

| Edge skiving | Skiving knife, round knife | Smooth, even finishing |

| Fringes and large cuts | Rotary cutter, utility knife | Speed and consistency |

| Strap making | Strap cutter | Consistent widths, perfect for belts |

| Lace making / braiding | Lace cutter | Scrap recycling, continuous laces |

Conclusion: which cutting tool for your leather projects?

Each leather cutting tool serves a specific purpose. Whether you are a leather artisan, fashion designer, or passionate about DIY leathercraft, choosing the right tools will save you time and give you clean cuts. To go further, build your toolkit gradually according to your projects and always prioritize tool quality, which ensures durability and precision.